Avinya Leather Pvt. Ltd. is spearheading a materials revolution—reimagining the very essence of leather through groundbreaking innovation, environmental stewardship, and ethical design. Driven by a bold mission to eliminate the ecological damage caused by traditional leather, Avinya has developed high-performance, plant-based vegan leather using agricultural residues, primarily wheat and rice straw. This transformation of waste into value results in cruelty-free, biodegradable materials that align with the rising demand for sustainable alternatives across industries.

But Avinya offers more than a product—it delivers a radical shift in material science and conscious consumption. The company’s vegan leather is 100% plant-based, non-toxic, and completely free from animal exploitation or harmful chemicals. By converting agro-waste into durable and customizable materials, Avinya not only curbs landfill overflow but also actively combats stubble burning—one of India’s leading contributors to air pollution—while empowering rural communities through job creation.

Avinya’s materials are engineered for global use, seamlessly integrating into fashion, lifestyle, home decor, and accessories. With backing options like 100% cotton, the products ensure aesthetic sophistication without sacrificing performance. Unlike synthetic substitutes derived from petroleum-based plastics, Avinya’s solutions boast a low carbon footprint, use significantly less water, and foster a circular economy.

Moreover, Avinya doesn’t walk this path alone. The company collaborates with visionary brands, designers, and manufacturers who are committed to pushing the boundaries of sustainability. These partnerships go beyond transactions—they are strategic alliances aimed at co-creating a greener, more responsible future.

As a brand, Avinya stands at the intersection of ecological consciousness, design excellence, and technological ingenuity. It represents what’s possible when performance meets purpose—a future where materials uplift the planet rather than deplete it.

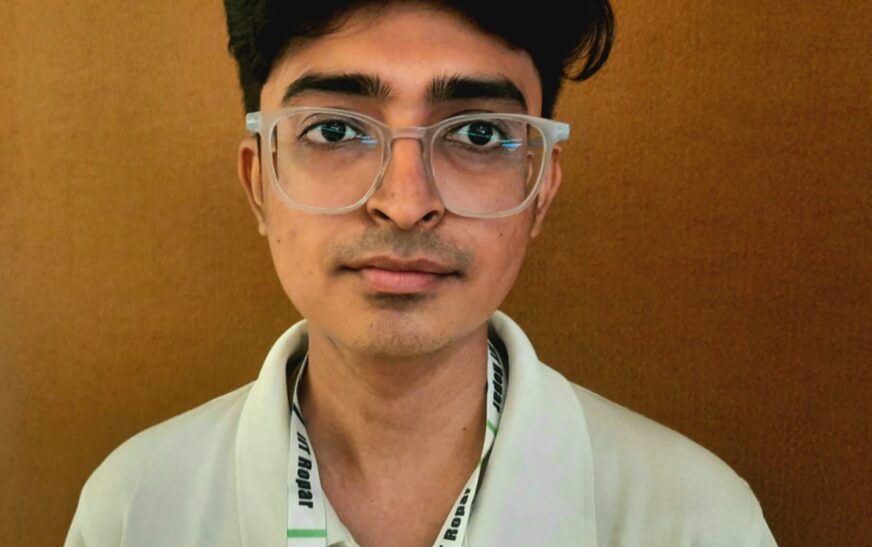

In an exclusive conversation with The Interview World at the PRAGATI Founders Forum 2025—hosted by iHub – AWaDH at IIT Ropar—Jenil Gandhi, Founder of Avinya, sheds light on the innovative journey of converting stubble into premium vegan leather. He shares insights on the company’s scalable operations, minimal investment requirements for production units, product development in the fashion segment, and its accessible pricing model.

Here are the key takeaways from this illuminating dialogue.

Q: Can you elaborate on Avinya’s core offerings and how they differentiate the company in its industry?

A: We are producing plant-based vegan leather using agricultural residues—primarily wheat and rice straw, commonly referred to as stubble. Currently, we operate on a B2B model, focusing solely on manufacturing the material and supplying it to exporters, product manufacturers, and D2C brands.

However, we are gradually expanding into the corporate gifting segment. Several companies have already placed orders, expressing a strong interest in products crafted from our sustainable leather alternative. This marks a promising step toward diversifying our offerings and tapping into new markets driven by conscious consumption.

Q: When did you launch this venture, and what core technology enables the transformation of straws into vegan leather?

A: About eighteen months ago, while still in college, I co-founded Avinya Leather with my roommate, Manan Vyas, who now serves as my partner in this venture. What began as a dorm-room idea quickly evolved into a bold leap toward sustainable innovation.

At the heart of our startup lies a proprietary technology that upcycles agricultural waste, specifically wheat and rice straw (parali), into durable, leather-like sheets. These sheets undergo environmentally responsible coating and finishing processes, meticulously engineered to replicate the texture, aesthetics, and performance of conventional leather. Crucially, we achieve this without relying on animal products or harming the planet.

Our material is not just innovative, it is scientifically validated. Developed in collaboration with top research institutions, the technology has undergone rigorous lab testing to ensure it is biodegradable, scalable, and industrially viable. Today, it is being tailored for applications across fashion, lifestyle, and accessory sectors, signalling a shift toward a more responsible and regenerative future.

Q: How sustainable is your product, and what strategies are you pursuing to scale it commercially in the near future?

A: Our material is 100% eco-friendly and fully biodegradable. We have secured certifications from multiple regulatory bodies that validate the sustainable nature of our products. At present, we are prioritizing price competitiveness to ensure our offerings remain accessible and attractive in a cost-sensitive market. Ultimately, our goal is clear—to make this sustainable alternative widely available and reach the maximum number of consumers.

Q: How feasible and efficient is the production process of this vegan leather?

A: We are now focused on achieving complete standardization across our operations. Our team is actively refining and streamlining every step of the production process to ensure consistency and efficiency. Once we establish a fully standardized model in one unit, we will replicate it seamlessly across our facilities in other geographical locations. This approach will enable scalable growth while maintaining uniform quality and performance.

Q: Approximately how much stubble is required to produce one meter of vegan leather?

A: From just one ton of stubble, we can produce approximately 1,200 square feet of material—equivalent to about 1.1 meters in width. This high material yield underscores the efficiency and scalability of our process.

Q: What is the expected production capacity of a single manufacturing unit for vegan leather?

A: By operating two 12-hour shifts each day, we can manufacture approximately 1,200 square meters of vegan leather daily. This production capacity reflects both the efficiency of our process and the scalability of our operations.

Q: What types of products have you developed using this vegan leather?

A: So far, we have developed a wide range of fashion accessories, including shoes, laptop bags, wallets, and handbags. Building on this foundation, we are now preparing to expand into furnishing materials for the furniture and automotive industries. We’ve initiated conversations with several manufacturers in these sectors and are currently awaiting their feedback. Once we receive substantial orders, we will begin tailoring our materials specifically to meet their technical and design requirements.

Q: How does the pricing of your eco-friendly vegan leather compare to conventional and other alternative leathers in the market?

A: Currently, the market offers three main types of leather: animal skin, rexine, and the eco-friendly leather we produce. Animal skin leather commands an average price of around ₹1,200 per meter, with premium qualities costing even more. Rexine, on the other hand, is significantly cheaper, ranging from ₹120 to ₹600–800 per meter.

When it comes to sustainable or vegan leather, competitors typically price their products between ₹2,500 and ₹3,000 per meter. Our goal is to offer a more accessible price point, targeting ₹1,800 to ₹2,000 per meter. Given the novelty of both the product and the technology, initial prices will remain on the higher side. However, as production processes mature and scale, we expect costs to decrease, making our eco-friendly leather increasingly affordable for conscious consumers.