Karmath, a trailblazing Indian technology company, is redefining sustainability in energy-intensive industries through the development of rare earth-free electric motors. By eliminating the dependency on scarce and environmentally damaging rare earth elements, Karmath delivers a new class of electric powertrain solutions—eco-friendly, cost-efficient, and high-performance. Its advanced technology drives electrification across critical sectors, including electric vehicles, agriculture, and HVAC systems for buildings.

With a clear mission to cut energy consumption and boost system reliability, Karmath harnesses deep expertise in materials science, precision manufacturing, and innovative design. The result is a new generation of efficient, waste-free motor systems engineered for sustainability. As part of its vision to accelerate the global transition to clean energy, the company actively seeks collaboration with partners across the sustainability ecosystem.

In an exclusive interaction with The Interview World at the PRAGATI Founders Forum 2025—organized by iHub-AWaDH at IIT Ropar—Varun Sharma, CEO of Karmath, delves into the company’s groundbreaking offerings. He highlights the pivotal support provided by IIT Ropar, discusses the wide-ranging applications of Karmath’s technology, particularly in agriculture, unpacks the core engineering principles behind the motors, and outlines the roadmap for commercialization.

Here are the key takeaways from this illuminating conversation.

Q: Can you walk us through your startup’s flagship offerings?

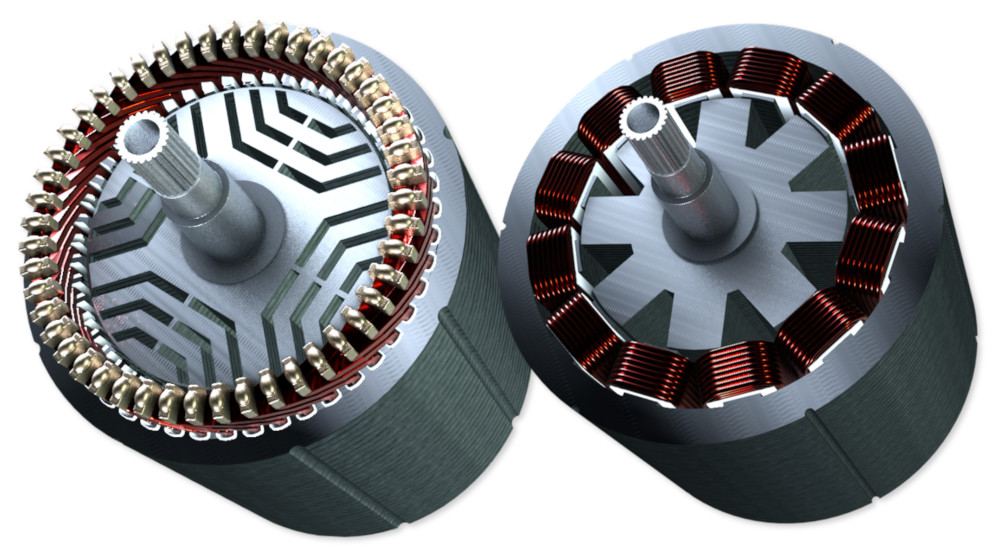

A: We are currently developing two core technologies. The first is a switched reluctance motor—a breakthrough design that eliminates the need for rare earth metals, unlike most conventional motors in use today. This innovation marks a significant step toward sustainable, resource-independent electric mobility.

Alongside motor development, we are also advancing solutions in energy storage systems—another critical frontier in clean technology. These two areas form the backbone of our R&D efforts.

The motor itself is complete. We are now finalizing the controller, a key component that will drive performance optimization. Commercialization is underway, and we are preparing to bring this cutting-edge solution to market.

Q: What kind of support or mentorship has IIT Ropar provided to your startup?

A: I participated in the incubation program at IIT Ropar, and their support has been instrumental to our journey. They’ve guided us through critical stages—helping us identify the right growth strategies, navigate fundraising, and deploy capital effectively. Beyond business mentorship, we’ve engaged in deep discussions around our core technology and the intricacies of patent filing. Their consistent handholding has provided both clarity and confidence as we scale our startup.

Q: How do your products aim to transform or add value to the agriculture sector?

A: Our products are designed to replace existing technologies fundamentally. A key distinction lies in the fact that our motors require no rare earth metals. This breakthrough enables fully localized supply chains. Consequently, the entire motor can be manufactured in India without relying on any imports.

Q: Which industries are the primary target markets for these motors?

A: Every industry that relies on motors will adopt this technology. Agriculture, in particular, stands out as a primary sector that will benefit significantly.

Q: Do you see your products playing a transformative role in shaping the future of the motor industry?

A: Yes, axial flux motors and switched reluctance motors represent the next frontiers in electric motor technology. Once these technologies gain traction, they will trigger significant disruptions across the industry.

Q: What are the core engineering or scientific principles driving the design and development of these motors?

A: Motor technology has existed for decades. What has truly evolved is the advancement in electronics. Modern systems must efficiently switch large volumes of energy signals in real time. This capability has now become mainstream. However, the critical missing piece was sophisticated algorithms to manage this process effectively. These algorithms must be embedded into the motor controllers. That gap no longer exists—our team has successfully developed and integrated these advanced algorithms into our controllers.

Q: At what stage of commercialization are your products—have they been launched, or are they nearing market readiness?

A: We are not yet market-ready. While the motor is fully developed and successfully tested with a discrete controller, we are currently finalizing the integrated controller. Once this controller is complete, we will launch the product into the market.