Founded in 2012 in Prague, Czechoslovakia, Prusa Research has transformed the landscape of desktop 3D printing. What began as a solitary endeavor in a modest basement has grown into a global manufacturing titan, now employing over 1000 professionals. Today, the company ships more than 10,000 printers each month, powering a worldwide community of makers, professionals, and enterprises.

The turning point came with the Original Prusa i3—an open-source, FDM 3D printer that quickly became a global favorite. By blending affordability, dependability, and modular upgradeability, Prusa made industrial-grade 3D printing accessible to the masses. At the heart of its innovation lies a steadfast commitment to open-source principles, showcased by its robust, in-house PrusaSlicer software.

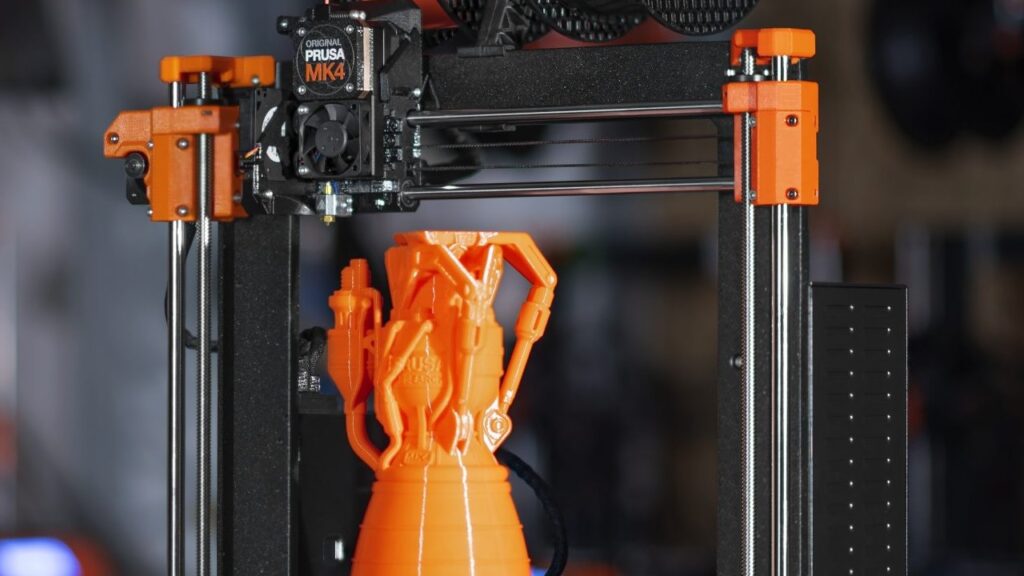

But the innovation doesn’t stop there. Prusa operates one of the world’s largest 3D printer farms, with over 600 machines working in unison to produce components for future printers. This self-sustaining, closed-loop production system underscores the company’s engineering brilliance. In 2024, Prusa extended its reach to the United States through its subsidiary, Printed Solid, significantly reducing delivery times and strengthening customer support across North America.

Sustainability remains deeply embedded in Prusa’s mission. The company manufactures recycled filaments, optimizes packaging to reduce waste, and continuously integrates eco-conscious practices into its operations. By fusing cutting-edge technology with environmental responsibility, Prusa Research continues to shape the future of additive manufacturing—layer by meticulously crafted layer.

At the Delhi Machine Tool Expo 2025, The Interview World engaged in an exclusive conversation with Tommy Muszynski, Technical Support Engineer at Prusa Research. He delved into the company’s key 3D printing solutions and innovations, offered a glimpse into their Indian operations, and highlighted the wide spectrum of industries leveraging Prusa’s machines. Notably, he emphasized tailored solutions for toy manufacturing and spotlighted the design files available on their website, accessible under a license agreement.

Here are the key insights from this compelling dialogue.

Q: What are the key 3D printing solutions and innovations currently offered by Prusa Research?

A: Prusa Research, headquartered in the Czech Republic, stands at the forefront of 3D printing innovation. For nearly 13 years, we have been designing and manufacturing high-performance 3D printers that have earned global recognition for their reliability and ease of use. From humble beginnings with just two employees, we have grown into a team of over 1,000, expanding our footprint across Europe and into the Americas.

Our journey has been defined by relentless growth and technical excellence. At the core of our product line is the acclaimed MK series, with the latest iteration being the MK4S. These printers are renowned for their rock-solid stability, minimal maintenance needs, and near-indestructible build—making them a preferred choice for professionals and hobbyists alike.

Additive manufacturing with Prusa printers is remarkably straightforward. Users simply prepare a file—any standard STL format will do—and the machine takes care of the rest. Our printers are compatible with a wide range of 3D printing materials, and we provide pre-configured profiles to streamline the setup process. Whether you’re printing with PLA, PETG, ABS, or advanced composites, our systems are ready to handle it.

We offer two configurations to suit different user preferences: fully assembled units and DIY kits. The assembled version is plug-and-play—unbox it, power it on, and you’re ready to print within minutes. The kit version, meanwhile, invites users to build the machine from the ground up. We supply every part, component, and a detailed guide to support the assembly process.

While assembling a printer may seem daunting, it’s one of the most effective ways to understand the inner workings of 3D printing technology. Building it yourself cultivates confidence in troubleshooting and maintenance, while also providing a deep sense of accomplishment. Depending on your experience, the full assembly typically takes between 8 to 12 hours—and the learning gained is invaluable.

Q: Could you provide an overview of your operations in India?

A: This marks the beginning of our exploration into the Indian market. While our presence here remains limited, we’re genuinely excited to be on the ground for the first time—especially in Delhi. We’re closely observing the market response, and so far, the reception has been overwhelmingly warm. Encouraged by the high level of interest, we are very likely to return next year to further strengthen our footprint.

Q: Which industries or application domains benefit the most from 3D printing technology in terms of efficiency and productivity?

A: Our machines seamlessly integrate multiple industries and serve a range of purposes. For instance, many parts of the machine itself are 3D printed. In our own factory, we operate 700 machines that continuously run, producing parts for our own use. These machines also enable consumers to create their own parts. One of the standout applications is rapid prototyping for large companies. Industry giants like Volkswagen, along with other major clients, rely on our machines. In fact, nearly every engineer at these companies has a machine on their desk.

This accessibility allows engineers to quickly print parts for prototyping or testing, enabling immediate evaluation before progressing to more costly manufacturing methods.

Q: Do you offer 3D printing solutions specifically designed for toy manufacturing?

A: Toys are absolutely possible and ideal for the general consumer. Whether you want to print gifts, toys, or hobby-related items, getting started is incredibly simple. We also provide access to our website, Printables, which hosts over 200,000 models. On this platform, you can easily browse and download any model you like, then print it yourself. For instance, many of our toys feature a QR code. Scanning the code directs you to the website, where you can download the model and print it on your own 3D printer. This makes it exceptionally easy for anyone to dive into 3D printing with minimal effort.

Q: Are the design files available on your website open for public use, and are there any restrictions associated with them?

A: Absolutely. When you upload your models to our website, we offer incentive programs to reward your contributions. If your models receive a certain number of likes and downloads within a set time frame, you earn pressure meters. These pressure meters can be redeemed as vouchers in our e-shop, allowing you to purchase items, including a 3D printer, if you accumulate enough points. We strive to recognize and reward those who contribute valuable models to the platform.

Additionally, when uploading a model, you can choose from several licensing options. This gives users the flexibility to specify whether the model is available for sharing and printing, but not for resale or retail use. Depending on the chosen license, certain restrictions apply, giving users full control over the security and usage of their models.