ManufApp revolutionizes the manufacturing industry by offering comprehensive solutions that streamline processes, enhance productivity, and optimize efficiency. Focusing on harnessing the power of technology, ManufApp provides a suite of tools and services tailored to meet the diverse needs of manufacturers across various sectors.

As a centralized hub for all manufacturing operations, ManufApp integrates essential functions such as inventory management, production scheduling, quality control, and supply chain management. This cohesive platform empowers businesses with real-time visibility into their operations, enabling data-driven decisions and rapid adaptation to changing market demands.

In an exclusive exchange with The Interview World, Apar Sureka, Founder and CEO of ManufApp, highlights how his company empowers manufacturing businesses to improve productivity and efficiency. Here are the key insights from his interview.

Q: How would you describe the scope of ManufApp’s operations, including the specific services and products it offers to the manufacturing industry?

A: ManufApp empowers manufacturers to enhance efficiency and lower inventory costs. Manufacturers often struggle with critical questions: Can they meet customer deadlines? Are their machines operating efficiently? Do they maintain optimal inventory levels? ManufApp addresses these challenges by digitizing factory operations and integrating seamlessly with accounting software. This integration provides complete visibility, enabling manufacturers to maximize operational output while minimizing costs.

Q: Given your extensive experience in automating the manufacturing segment and integrating manufacturing software operations, what emerging technologies are you incorporating into your solutions?

A: We leverage AI, machine learning, and computer vision, as the entire industry advances towards IoT 5.0. This shift enables us to gather real-time data from various machines, analyze these parameters instantly, and provide immediate recommendations. Consequently, actions that previously took days, weeks, or even months can now be executed in a much shorter timeframe. By utilizing cutting-edge technologies like cloud computing and AI, we deliver exceptional services efficiently and effectively.

Q: Could you quantify the potential increase in efficiency that can be achieved using your application?

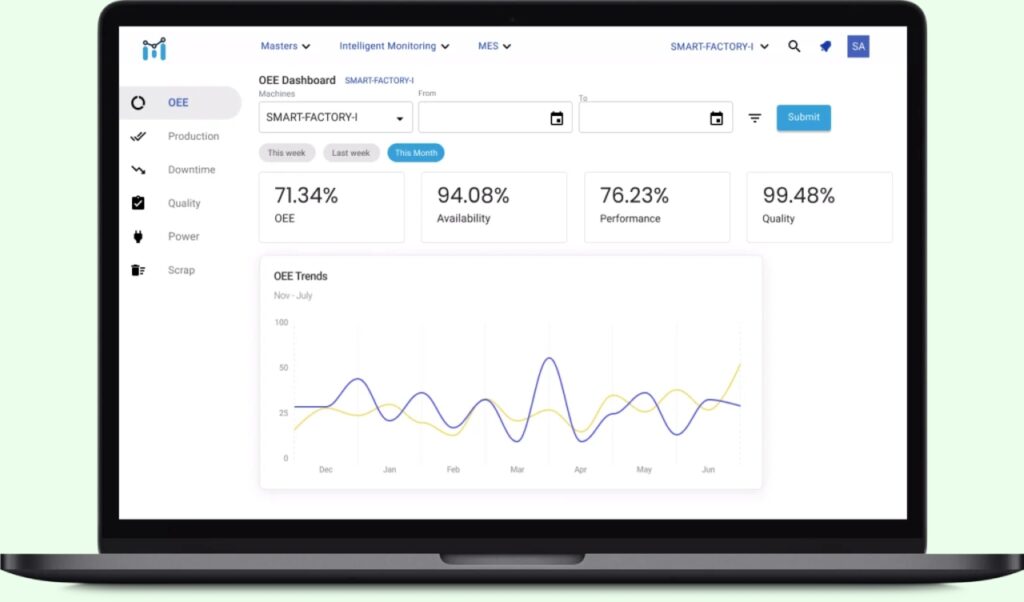

A: When discussing machine efficiency, specifically Overall Equipment Effectiveness (OEE), our customers have experienced notable improvements. They have seen an increase in OEE by approximately 10 to 12%, which has significantly enhanced their ability to serve their customers on time, with an impressive 20% improvement. Additionally, inventory optimization has led to a reduction in stockouts by about 12%.

Q: Does your solution contribute to cost reduction?

A: Our software caters primarily to individuals seeking profitable growth. We’ve observed that many manufacturers find themselves trapped in their operations, hindering their ability to prioritize growth. Thus, we intervene to assist them in streamlining operations, enabling them to focus on expansion. Consequently, as they grow without incurring additional costs, their overall expenses naturally decrease.

Q: Could you provide an analysis of the current market size for your industry both in India and internationally?

A: The global manufacturing execution system (MES) in which we operate commands a market worth $7 to $8 billion. Every manufacturing company of a certain size necessitates our software or similar manufacturing solutions. In today’s evolving landscape, constant presence on the shop floor is impractical. Hence, effective management requires sophisticated software solutions like ours. Therefore, every manufacturer must integrate such software into their operations.

Q: Can you share your vision for where you see your company in the next five years? What are your long-term goals and objectives?

A: Our vision entails empowering manufacturers, fortifying their capabilities, and catalyzing the realization of India’s industrial aspirations. We are dedicated to fostering growth, enhancing market penetration, and ensuring accessibility. With a primary emphasis on electronic manufacturing fabrications, our goal is also to ensnare one in every ten electronic manufacturers as our clientele within the next five years. Moreover, we aim to extend our presence to strategic locales such as Vietnam and Southeast Asia. Furthermore, we are already catering to Spanish and Japanese clients, and we intend to further expand our footprint in these regions.

Q: What response are you receiving from Indian manufacturing companies?

A: Indian manufacturers have transitioned into the second and third generations. With this shift, there’s a growing demand for increased data and freedom, surpassing traditional shop floor management. This signals a new era marked by digitization, previously absent in the industry. Alongside digitization, there’s an infusion of fresh energy and perspectives from the younger generations. They’re poised to scale operations in alignment with the evolving ecosystem.