The Apparel Training and Design Centre (ATDC) stands as India’s foremost vocational training institution dedicated to the apparel sector. With a presence in 22 states and a network of nearly 100 centers, it holds the distinction of being the country’s largest provider of high-quality vocational training in this domain. ATDC’s guiding philosophy—”By the industry, For the industry, and With the industry”—reflects its unwavering commitment to addressing the apparel sector’s evolving demands.

ATDC offers a diverse portfolio of programs, including degree, diploma, and certificate courses, meticulously designed to equip students with the skills essential for various roles in apparel manufacturing. The institution prioritizes underprivileged youth and women, reinforcing its mission of “Imparting Skills – Improving Lives.”

Since its inception, ATDC has trained over 250,000 candidates, with 60% securing employment in the apparel industry, while others thrive in the informal sector or through self-help groups. Backed by 400 resources and 300 faculty members, ATDC ensures exceptional training quality and boasts an impressive 75% placement rate.

Beyond training, ATDC plays a crucial role in skill development initiatives, collaborating with government projects, corporate social responsibility (CSR) programs, and state skill missions. These efforts further cement its position as a driving force in India’s apparel industry and workforce development.

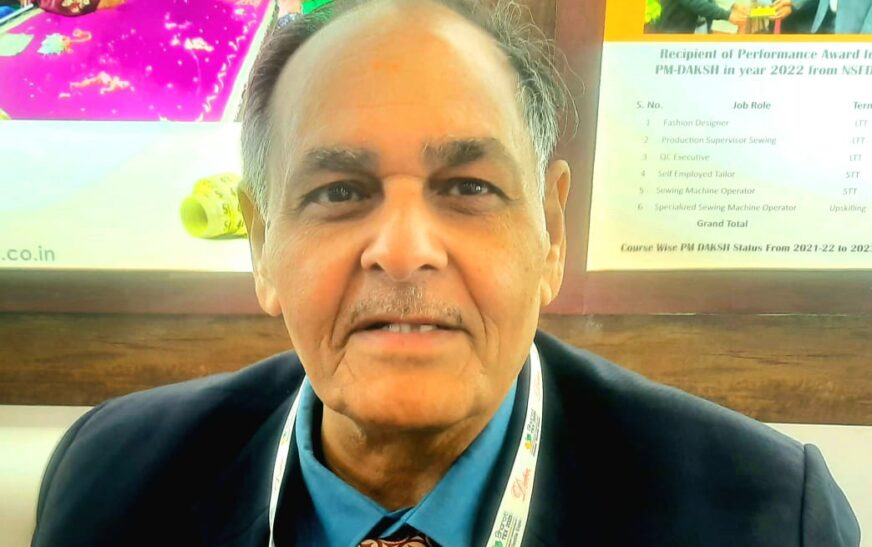

At Bharat Tex 2025, Dr. Vijay Mathur, Director General & CEO of ATDC, sat down with The Interview World to discuss his organization’s innovative strategies for equipping aspiring designers with cutting-edge skills and strengthening India’s global competitiveness in textiles. He highlighted sustainable apparel manufacturing technologies that ATDC is introducing, shared insights into game-changing innovations in functional textiles, and underscored India’s leadership in textile engineering and technology compared to other developed nations.

Here are the key takeaways from this insightful conversation.

Q: What innovative approaches is ATDC implementing in apparel design to equip aspiring designers with cutting-edge skills and enhance the global competitiveness of India’s textile industry?

A: At the Apparel Training and Design Centre (ATDC), design is at the heart of everything we do. Our expertise lies in training skilled professionals who can shape the future of the apparel industry. To advance this vision, we have introduced a specialized course in sustainable apparel manufacturing technology. This program integrates energy-efficient and water-saving production techniques, emphasizing waste minimization while ensuring that designs remain classy, functional, and accessible to the masses.

Innovation drives our approach to apparel design. We create elegant yet affordable garments, ensuring durability that extends beyond just a few wears. Instead of contributing to textile waste that pollutes oceans, we focus on long-lasting, sustainable fashion. Our mantra—Classy, Local, and Affordable—guides every design we produce.

Over the past 25 years, ATDC has trained over 400,000 students across 91 centers in 22 states. We focus on grassroots talent, particularly school dropouts and those unable to pursue engineering or medical careers but eager to build a livelihood. We provide structured training programs ranging from three months to a year, equipping them with industry-relevant skills. More than just training, our mission is employment-driven—ensuring that every student secures a job in the apparel sector.

At ATDC, we don’t just teach fashion; we shape futures.

Q: What sustainable apparel manufacturing technologies are you introducing to the market, and how can they be adopted by other industry players and institutions to drive broader sustainability in the sector?

A: Sustainability varies across sectors. In the apparel industry, the numbers are staggering—every year, 100 billion garments are produced for a global population of 8 billion. Consumers buy impulsively, stuffing their wardrobes with clothes they don’t need. They purchase endlessly, unaware of the waste they generate.

Meanwhile, cotton cultivation demands immense water resources. On one hand, millions lack access to clean drinking water. On the other, vast amounts are diverted to grow cotton for garments that often go unused. This imbalance underscores the urgent need for responsible fashion.

In apparel manufacturing, we advocate for smarter design choices. Reduce material usage—why should a shirt have six buttons when two suffice? Innovate to create fabrics that require less frequent washing. Prioritize durability over disposability. These principles form the foundation of sustainable apparel technology. By optimizing fabric consumption and leveraging advanced techniques, we produce only what is necessary. The goal is simple: conserve resources today to secure a sustainable future.

Q: What innovations is your organization driving in functional textiles to enhance advanced features in apparel manufacturing?

A: We actively engage in product development, pushing the boundaries of functional apparel. Take mountaineering gear, for instance. Climbers venturing into extreme conditions need garments that withstand temperatures as low as -10°C or even -20°C. The challenge lies in designing fabrics that provide insulation, protection, and durability. From gloves and hats to trousers and jackets, each piece must be engineered for survival.

The industry is innovating new functional fabrics, and we transform them into high-performance garments. Beyond apparel, advancements now extend to parachutes and other extreme-use textiles. One critical area of focus is noise reduction. Consider this: India has added over 150 airports, leading to a surge in air traffic. More aircraft in the sky means increased noise pollution. Sustaining exposure to over 80 decibels becomes unbearable. This presents an opportunity—can we design garments that shield individuals from excessive noise?

These futuristic applications are still in the research phase, but the need is inevitable. In 50 years, air taxis will fill the skies, intensifying noise pollution. Innovations won’t stop at clothing. Glass panes will evolve to block sound while allowing airflow and sunlight.

While we specialize in apparel today, the future holds broader possibilities. Imagine a curtain that blocks noise yet lets air and light pass through. This is the next frontier—challenging, but within reach.

Q: How does the Indian textile industry compare to that of developed nations in terms of textile engineering and technology?

A: India’s clothing industry thrives on deep-rooted cultural and societal support. From Kashmir to Kerala, sarees and traditional attire remain an integral part of weddings and celebrations. Wearing well-crafted garments is ingrained in our lifestyle, ensuring sustained demand for apparel. As consumption grows, the retail landscape is evolving—malls are now emerging even in tier-three cities.

India’s economic ecosystem is also transforming rapidly. Consider this—₹20 lakh crore worth of UPI transactions occurred in just one month. Digital adoption is accelerating, seamlessly integrating businesses with suppliers. Unlike other developing nations, India’s 140-crore population operates under a unified currency. By 2050, this number will reach 1.66 billion, further amplifying our domestic consumption power. This self-sustaining demand will gradually shift our focus from exports to an expansive internal market. As disposable income rises, spending patterns will evolve, fueling unprecedented growth.

The bigger picture extends beyond textiles. India’s progress hinges on connectivity, communication, and skill development. Digital platforms now enable businesses to connect, filter leads efficiently, and scale operations strategically. The challenge lies in integrating skilled professionals into this ecosystem while leveraging digital tools for seamless business operations.

The future of India’s textile sector looks promising, but it cannot be viewed in isolation. Its success ties into broader advancements across digital infrastructure, engineering, material science, fashion innovation, and sustainability. The industry is evolving rapidly, keeping pace with global trends and technological transformations. India is not just catching up—it is poised to lead.